Index Home Desert-Electricity World Deserts Electric Network Types of Produktion Comparison Water Network Hydrogen New Industry Green Cities Energy Transition Imprint

Photovoltaics

Conclusion:

The costs of manufacturing and subsequent disposal are enormous and reduce the benefits of such systems. The performance and value of a photovoltaic system decreases quickly. After ten years, a PV system is only worth half. After 25-30 years, the systems and their attachments are scrap that needs to be replaced.

The production and disposal of the solar panels and the required electrical-electronic attachments, especially the batteries, require a lot of energy and unfortunately up to 90% of this is currently produced from fossil fuels. Recycling and all the logistics required for this technology only work using fossil fuels. Burning the remains of a photovoltaic system produces significant amounts of CO2 and toxins. Hazardous waste landfills are necessary to store the remaining material. Of course, this significantly reduces the actual production of climate-neutral energy.

It would therefore be logical to limit the use of photovoltaics as long as the questions of climate-neutral production and recycling of materials have not yet been clarified.

In Detail:

The production of photovoltaic modules is a complex process that ranges from the extraction of silicon from quartz sand to the final testing of the finished module. To produce monocrystalline solar cells, silicon is melted and purified. A rod is then drawn from this melt, which forms a uniform crystal lattice, a so-called single crystal or monocrystal. These ingots are then cut into thin wafers and processed into solar cells. A distinction is made between polycrystalline and monocrystalline solar cells as well as thin-film cells. Silicon melting is required for all types. A process that requires a lot of heat and, with today's energy mix, releases a lot of CO2.

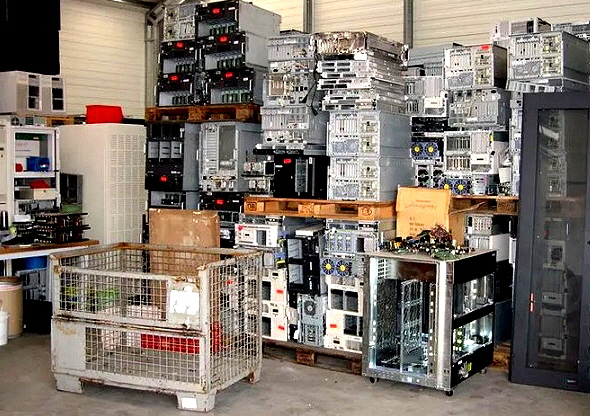

An enormous amount of additional technology is required

A photovoltaic system requires a lot of electronic and electrical equipment in order to make electrical energy usable for the household, as the direct voltage from these panels is low and the panels do not generate high power. If they were overloaded they would get hot and start to burn. Therefore, the energy must be temporarily stored in batteries in order to reach a certain performance level. This storage must be controlled via a control device so that the battery does not become overcharged and start burning. The direct voltage from the battery must now be converted into a higher alternating voltage in an inverter, which in turn must be monitored so that the battery does not become overloaded and start to burn. The batteries required in particular leave a significant negative ecological footprint. Today's battery recycling technology also consumes huge amounts of, unfortunately, still fossil energy.

The biggest problem with photovoltaics is the structure, which limits the service life of the panels. Immediately after commissioning, the solar cell begins to decrease in performance. This normal process, which is triggered by the movement of electrons, which essentially causes the atoms to disintegrate due to a lack of energy, is called degradation and causes a loss of performance of up to 80% in the solar modules after 25-30 years of operation. After ten years, the value of a photovoltaic system is halved. Replacement is necessary after 25-30 years of operation.

Where to put the gigantic amounts of waste?

According to reports, China will generate the largest share of PV waste by 2050, at 13.5 million tons. The USA follows with 7.5 million tonnes, Japan with 6.5 million and India with 4.5 million tonnes. Germany comes in fifth place and could accumulate around 4.4 million tons of discarded PV modules by 2050. Europe's largest solar module recycling plant only recycles around 4,000 tons per year.

Recycling

The energy used for recycling is currently made from up to 90% fossil fuels. The logistics required for this still only work using fossil fuels. The whole process causes more environmental damage than benefit.

Another very big disadvantage is that the material made of silicon, copper, silver, indium, cadmium, lead, selenium, tin (depending on the type), which is produced in a complex process, cannot be separated and returned to the manufacturing process. The plastics are converted into gases such as methane, propane and butane, which are then burned again and in turn produce CO2. The recycling rate is only around 70-90%. The trick with so-called recycling is, on the one hand, the glass; it makes up around 60-70% of the weight, the frames around 10-20%. So it is of course very easy to achieve a recycling rate of 70-90%. It is not necessary at all to remove the material bound in the cell structure. The remains, around 10-30%, end up in hazardous waste landfills. Due to the truly gigantic amounts of waste that are to be expected in the future, 10-30% of this is at least 4-12 million tons of toxic material that will end up in landfills in the first wave alone and will not be recycled.

So we produce hazardous waste, very complex, with a lot of energy, sometimes with rare metals, which we get from the sea or the ground, destroying nature in the process and then simply throwing them away.

Many more raw materials could be reused

In a recycling process, the solar panels are dismantled, which means shredded, glass, aluminium, silicon, plastic and copper are mechanically separated and unfortunately only partially processed into new solar panels. Silver, indium, cadmium, lead, selenium and tin cannot yet be separated. Because chemical separation is not yet possible.

That is why it is extremely important to finally conduct research into the chemical separation and recycling of such materials.

To be clear, I am not against photovoltaics per se, but rather against the fact that something is simply produced without knowing exactly how it can be transformed back into what it was before and instead, usually even thrown into our living space in a highly toxic. Despite the precise knowledge about millions of tons of highly toxic hazardous waste that will be generated and lying around somewhere, it will simply continue to be produced. This is really irresponsible. The most irresponsible thing, however, is that the legislators allow producers to simply produce something WITHOUT any responsibility for their products. For me it is clear: If you want to produce something, you have to take the product back after use and completely dismantle it into the original raw materials. Throwing it into nature just doesn't work. Only substances that are natural may be stored in nature. There should also NOT be any hazardous waste dumps.

Burning that is rich in toxins is also not possible at all. The stuff comes down somewhere and poisons people, animals or the soil.

Decomposition into the original raw materials is possible. Even the recycling and complete annihilation of nuclear fuel elements is possible.

Of course this doesn't make any money but costs money. It may cost so much that a product can no longer be sold because it is too expensive.

But that is not an argument for committing a crime such as intentionally negligent bodily harm. Because nothing else is the introduction of poisons into the habitat of living beings, also the creation of natural disasters through unnecessary warming of the earth's surface.

It is more of an argument for not producing the product or for suspending production until the problems with the product have been resolved.

One solution would be to systematically increase the price of raw materials, as this measure would make recycling lucrative.

Further topics:

Index Home Desert-Electricity World Deserts Electric Network Types of Produktion Comparison Water Network Hydrogen New Industry Green Cities Energy Transition Imprint